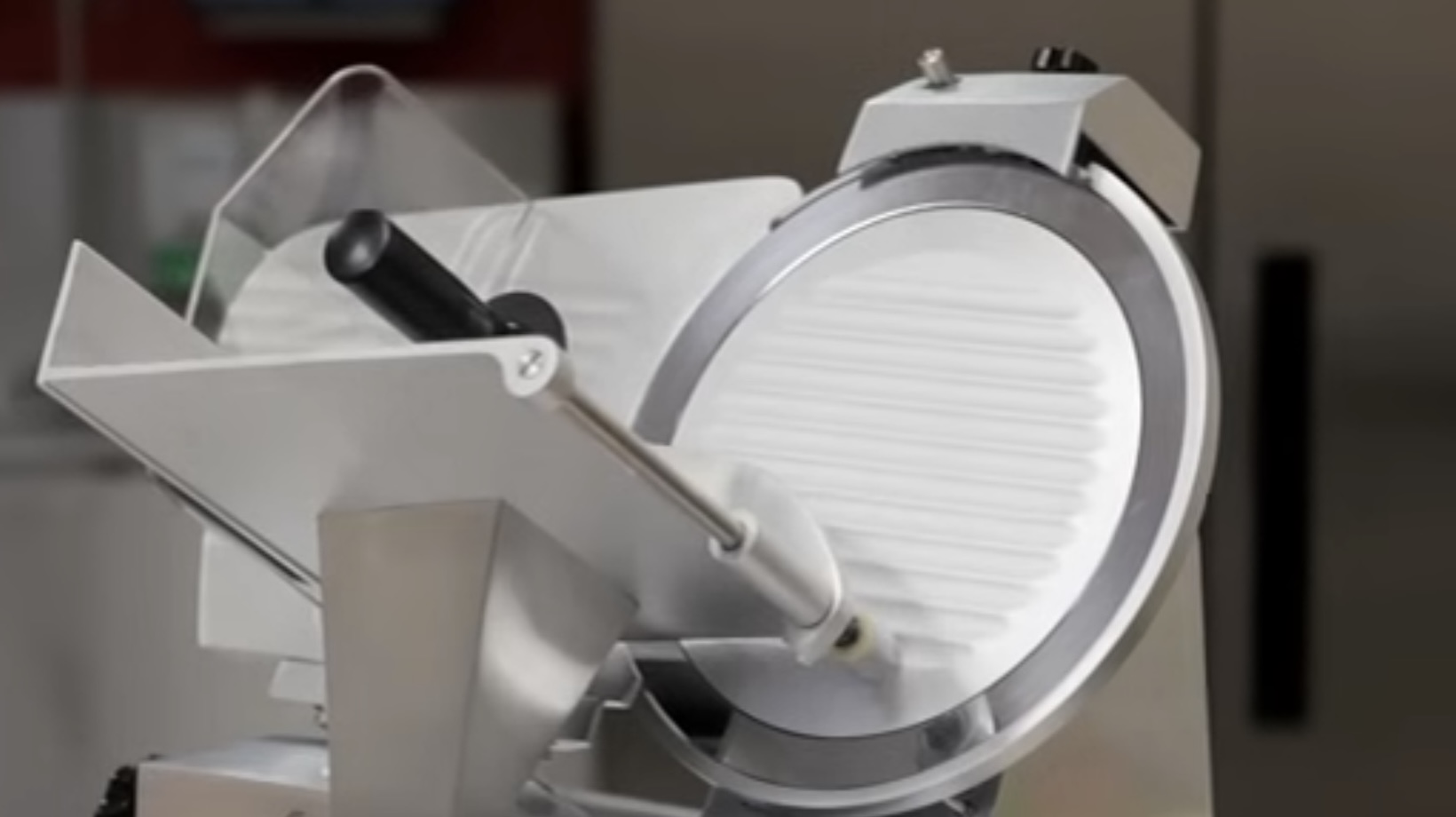

Why Cleaning and Sanitizing a Meat Slicer Is Important

Proper hygiene and maintenance of kitchen equipment are critical in ensuring the safety and quality of food served. A meat slicer, especially, is a hub for potential cross-contamination if not cleaned and sanitized regularly. This section explores the reasons why investing time in the cleaning process not only maintains food safety but also complies with health regulations.

Ensuring Food Safety

Food safety is paramount in any food service operation. A meat slicer is frequently used and comes into contact with various types of food, making it a likely candidate for harboring dangerous bacteria. Here’s why rigorous cleaning and sanitizing procedures are non-negotiable:

- Cross-contamination: Residual food particles can lead to the growth of pathogenic microorganisms.

- Bacterial growth: The warm, moist environment of a slicer is ideal for bacteria like Salmonella, Listeria, and E. coli.

- Allergen sources: Leftover residue can trigger allergic reactions in sensitive individuals.

Keeping a meat slicer spotlessly clean is not just about aesthetics; it’s about preventing foodborne illnesses. Regularly scheduled cleaning breaks down biofilms, impedes bacterial growth, and ensures that allergens don’t linger on the slicing blades and surfaces.

Compliance with Health Regulations

Beyond the direct health implications, there are stringent regulatory reasons behind maintaining meat slicer hygiene:

- Health codes: Food service establishments must adhere to local, state, and federal health codes, which often dictate equipment cleanliness.

- Inspections: Unexpected health inspections can flag inadequately cleaned equipment as violations, leading to fines or closures.

- Certification: Some jurisdictions require certified training on equipment sanitation for operators.

Standardized cleaning and sanitizing practices are legally mandated to ensure public health. Compliance with these regulations not only safeguards the reputation of a food service business but also protects it from potential legal complications associated with food safety violations. Commitment to these protocols demonstrates a conscientious approach to customer health and well-being.

Before Cleaning and Sanitizing a Meat Slicer Servsafe

Using a Sanitizing Solution

For meat slicers to be sufficiently sanitized, selecting EPA-approved sanitizing solutions is crucial. These solutions are effective against a broad spectrum of pathogens that are commonly found on food-preparation surfaces. In particular, they’re designed to combat the microorganisms that standard cleaning cannot eliminate. The ideal sanitizing solution should have clear instructions for dilution to ensure its effectiveness and safety.

When preparing the solution, it’s important for employees to follow the manufacturer’s guidelines precisely. The correct concentration is key, as overly diluted solutions may not be effective, while overly concentrated solutions can be toxic and could contaminate food. To verify the accuracy, staff can use test strips that measure the concentration of sanitizer in the solution.

Applying the Solution to All Surfaces

After cleansing the meat slicer, it’s vital to apply the sanitizing solution to every surface that comes into contact with food. This includes the:

- Blade

- Guard

- Slicer handle

Hard-to-reach areas should not be overlooked. Using a clean cloth or a spray bottle, workers should apply sanitizer thoroughly, making sure to cover all nooks and crannies where contaminants might hide. Disposable towels can be a better option than reusable cloths, which may harbor bacteria.

Allowing Sufficient Contact Time

For the sanitizing agent to be fully effective, it needs to remain on surfaces for a specific amount of time, often referred to as the contact time. This period allows the solution to break down the cell walls of bacteria, rendering them harmless. The necessary contact time varies based on the sanitizer but typically ranges from 30 seconds to several minutes.

Staff should consult the sanitizer label for exact times and ensure that the slicer remains undisturbed during this period. After the required contact time has elapsed, surfaces should either be left to air dry or rinsed with water, depending on local health regulations and the product’s specifications. Proper contact time ensures that the sanitization process reduces the risk of foodborne illness effectively.

Regular Maintenance and Inspection

Maintaining a meat slicer isn’t just about cleaning and sanitizing; regular maintenance and inspection play a crucial role in its longevity and safety. Food service establishments should ensure their meat slicers are routinely checked to ensure they operate optimally. This not only helps in preserving the quality of cuts but also contributes to the prevention of equipment failure and potential food safety hazards.

Lubricating Moving Parts

Keeping a meat slicer’s moving parts well-lubricated is essential for smooth operation and prevention of premature wear and tear. Food-grade lubricant must be applied to:

- The slide rod

- Bearings

- Components beneath the slicer carriage

The application should be in accordance with the manufacturer’s instructions to avoid any safety risks associated with improper use. Regular lubrication prevents the accumulation of food particles and debris, which could otherwise lead to a breeding ground for bacteria.

Checking for Any Damages or Wear

Periodic inspections are vital in identifying potential issues before they escalate. Food service establishments should check their meat slicers for:

- Dull blades

- Loose or missing parts

- Signs of rust or corrosion

Damaged blades can result in uneven slicing or become a safety hazard to employees. Replacing or sharpening the blade as per the manufacturer’s recommendations ensures consistent performance and safety. Loose parts should be tightened and missing components replaced to prevent accidents and maintain the slicer’s integrity. Noticing and addressing rust promptly prevents further deterioration which could contaminate food products.

Inspecting and addressing issues immediately helps in extending the meat slicer’s life span and ensuring the safety and efficiency of its operation. It’s a proactive approach that can save significant time and resources in the long run, while also maintaining adherence to food safety standards.